|

It

is relatively easy to impliment and enforce the use of proper

static controls (such as wrist straps, grounded workstations,

etc.) at the manufacturing level. It

is relatively easy to impliment and enforce the use of proper

static controls (such as wrist straps, grounded workstations,

etc.) at the manufacturing level.

Unfortunately, unless proper packaging and handling

procedures are used after the product is shipped, the potential

risk for ESD damages remains.

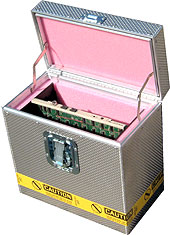

Recognizing that proper grounding and handling procedures are

not always followed in the field, rigidized aluminum cases are

used extensively by the electronics and telecommunications industry

sectors to minimize this risk.

Unlike ATA cases, rigidized aluminum shipping

cases and transit cases have a surface resistivity of 30 ohms,

providing superior EMI/RFI shielding properties and a natural

path for the dissipation of any static charge that may be present

over the outer conductive surface area.

When combined with the use of anti-static and/or

static dissipative cushioning materials, an equalization of electrostatic

potentials between handler and shipping case contents automatically

occurs, simply by opening the case.

By effectively providing anti-static isolation

within a conductive faraday cage, catastrophic (DOA) or latent

(No Fault Found) field reports are dramatically reduced using

rigidized aluminum shipping cases and transit cases, saving on

maintenance repair costs and maximizing revenues.

Click

here to request a quote for ANTI-STATIC CASES.

|